WEAR ANALYSIS

of a thermal print head (case 22)

QUESTION:

Can you analyze wear characteristics of print heads?

A manufacturer of thermal printers had problems with the performance of thermal heads. Objectionable image quality failures were encountered after significantly less image copies than specified by the supplier of the thermal heads. We were asked to analyze the wear characteristics of the thermal print heads.

APPROACH:

Wear analysis

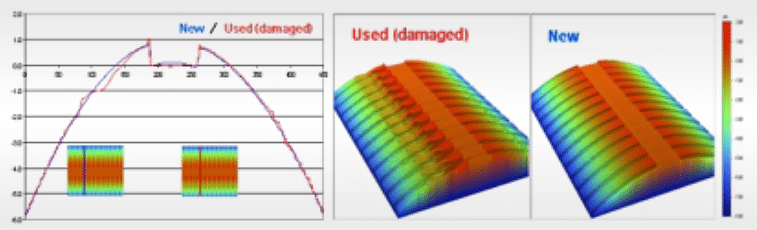

The mechanical profiles of the thermal print head were scanned with an optical profiler (white light interferometer). A 3D-topographic image is then reconstructed for ‘visual’ representation of the damage, which showed asymmetric wear on the individual heating lines that were embedded in a microstructured glass rod.

On the position of the individual heating lines, a 2D-profile analysis is derived as quantitative measure of the wear. This wear analysis was repeated for a number of thermal print heads under specified process conditions (number of copies, thermal film, thermal printer settings).

RESULT:

Improved thermal print heads

The well-performing thermal print head of an alternative supplier showed a symmetric wear profile that is typical for mechanical wear. The asymmetric wear pattern of the problematic print head also indicated chemical degradation of the glass rod because of a reaction with accumulated debris from the thermal film.

The supplier of the thermal heads was confronted with these findings. He took actions to replace of the sort of glass that was used for protection of the heating lines.

We can help you with any kind of wear analysis.

Let's Talk

Fill out this form, and we'll revert to you as soon as possible.

Please provide a detailed description of your question or request.