SMELL ANALYSIS

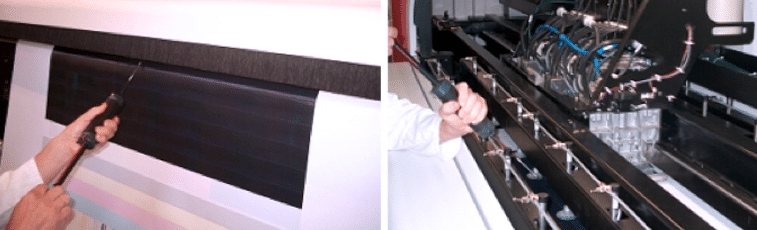

to solve odor problem with UV inkjet printer (case 01)

QUESTION:

What is causing the odor problem?

The client noticed an odor problem when certain types of paper were printed on a UV curable printer. That’s why he asked AgfaLabs for a smell analysis.

APPROACH:

Smell analysis

Air probes were sampled during printing in order to analyze the volatile components. Various solvents (toluene, acetone, methylenechloride, …) were found in the range below 1mg/m3.

In addition, thermal desorption experiments were run on samples of the non-printed papers, and two types of ‘bad smell’ could be reproduced and identified.

One of the papers thermally released trialkylphosphate and alkane in addition to traces of cyclohexylamine, which is used as paper sizing agent. The overall smell perception was ‘fishy’.

In another case, the smell of ‘burnt milk’ was identified, which could be related to the presence of casein in the paper: casein thermally degrades into lactates.

RESULT:

Different choice of paper

The thermal load of UV curing is sufficient to release certain volatile components from the paper or to cause thermal degradation. The UV irradiation was less relevant.

The smell analysis linked the cause of the odor problem to the choice of paper. High quality paper is recommended for these printers, because these are free of thermally instable components.

Experiencing a similar odor problem?

Let's Talk

Fill out this form, and we'll revert to you as soon as possible.

Please provide a detailed description of your question or request.