DELAMINATION

of freezer bags (case 04)

QUESTION:

What causes the delamination?

A manufacturer of freezer bags had a quality problem with one of his laminated tubular foils, which was used for protecting food in freezers.

The foil showed strong corrugation, when brought in contact with specific organic solvents. The foil rippled or even delaminated into two layers, undermining their protective function.

APPROACH:

Layer structure analysis

Our analytical approach was based on a systematic characterization of all interfaces of the laminated foil with respect to potential solvent attack.

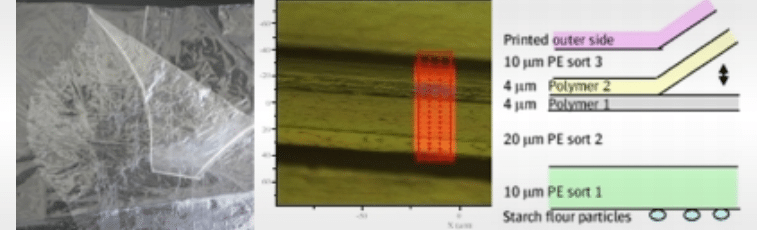

A light microscope investigation on a microtome cross section revealed something peculiar about the layer structure: one of the layers actually consisted of two layers. Based on FTIR and Raman mappings on the cross section, the two sub-layer materials were identified as different types of PE with a glue layer between them.

It was concluded that the solvents could diffuse through the lower PE sub-layer and dissolved the glue, whereas the other laminate interfaces were actually stable.

RESULT:

Alternative PE-foil

With this information about the delamination at hand, the freezer bag manufacturer could approach the vendor of the composite PE-foil, in order to look for an alternative.

Does this delamination problem sound familiar? We can help you determine the cause and find a solution.

Let's Talk

Fill out this form, and we'll revert to you as soon as possible.

Please provide a detailed description of your question or request.