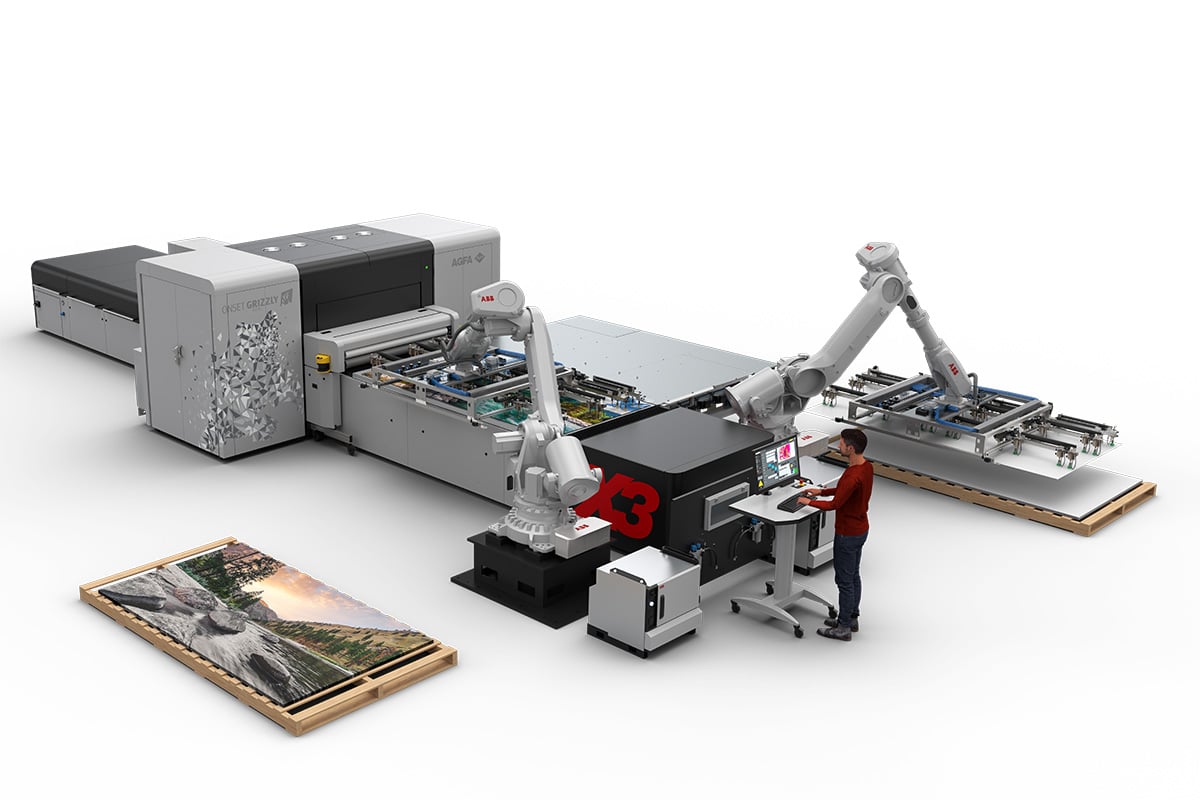

N Smith & Co purchases Onset with full automation

Agfa is celebrating the completion of the first UK installation of their fully automated Onset X3 HS print engine, at Midlands-based cardboard engineering specialist, N Smith & Co.

It has been a sizeable investment for the business who were determined to specify a machine that would support their business growth aspirations. According to MD Nigel Reynolds, the whole process has been very quick, and they would have struggled to get through a recent surge in business along with a lengthy breakdown on an existing machine without the new printer.

“Our experience with Agfa has been good right from the start and we really didn’t make the selling process easy for them. Since 2013, we have purchased 5 digital print machines including two Incas, an Arizona and an HP Scitex in 2018. We learnt a lot during those purchases and this time had very specific objectives. We wanted to go to the maximum spec with this new machine to reduce the strain on our existing printers as well as to satisfy growth with existing customers. We also wanted it to take the business to the next level to allow us to look for new opportunities and move into new markets.

The Onset has delivered some really good quality work, even better than I was expecting. We initially calculated that it would achieve the same level of workflow as our existing machines but on a whole shift less. Whilst this is an accurate calculation in reality this hasn’t happened as yet due to an unexpected influx of business.” said Nigel.

N Smith & Co was established in the centre of Birmingham in 1901 making solid board boxes for components in the automotive industry. It was a labour-intensive process and by the 1950’s they employed around 100 people and moved to their current site in Tividale, Oldbury. They continued with carton solid board boxes that housed industrial nails and hinges etc through the 1960s, 70s & 80s and then added corrugated box production to the business. The company passed to many generations of the original family up to the late 1990s when they went through a management buyout. They made conventional boxes only until the late 1990s when they started to use both silk screen and litho print for their products provided by external suppliers. In the early 2000’s they bought a screen print business and started in-house print production on the boxes they manufacture and in 2013 they purchased their first digital press. The business now employs 70 staff across 3 sites.

We sent some horrible print files and really bad substrates to Agfa in advance of our visit just to replicate some of our worst scenarios and for them to demonstrate on. The Agfa guys were brilliant and pretty much solved every problem. They convinced us it was the right machine.

The team from N Smith & Co initially contacted James Argent from Agfa in May 2023. They then visited Agfa in Antwerp to view the different options. It was the first demo that the Agfa technical team had delivered on the Onset X3 HS since the acquisition, but they passed with flying colours. Director and General Manager of N Smith & Co, Kerry Tyers was impressed, “We sent some horrible print files and really bad substrates to Agfa in advance of our visit just to replicate some of our worst scenarios and for them to demonstrate on. The Agfa guys were brilliant and pretty much solved every problem. They convinced us it was the right machine.”

L-R: Paul Fitch – Agfa, Nigel Reynolds MD at N Smith, Kerry Tyers Director & General Manager at N Smith, Gary Hogg Operations Director at N Smith and James Argent – Agfa by the newly installed Agfa Onset X3 HS print engine

Operations Director Gary Hogg added, “We placed the order in May and took delivery at the end of July and it was all ready to use with operatives trained by September. We started using the machine immediately as we had an unexpected amount of business along with a lengthy breakdown on an existing machine, so the operatives had to get up to speed quickly. They find the automation excellent. It’s difficult to quantify how much time you lose by someone manually feeding a machine whereas with complete automation you eliminate this. Manually feeding cardboard onto a printing machine can get very intensive, some of the boards are 1.5 x 2.8m and the operative must lift 4-5 boards at a time, so automation is a lot better for the operator too.”

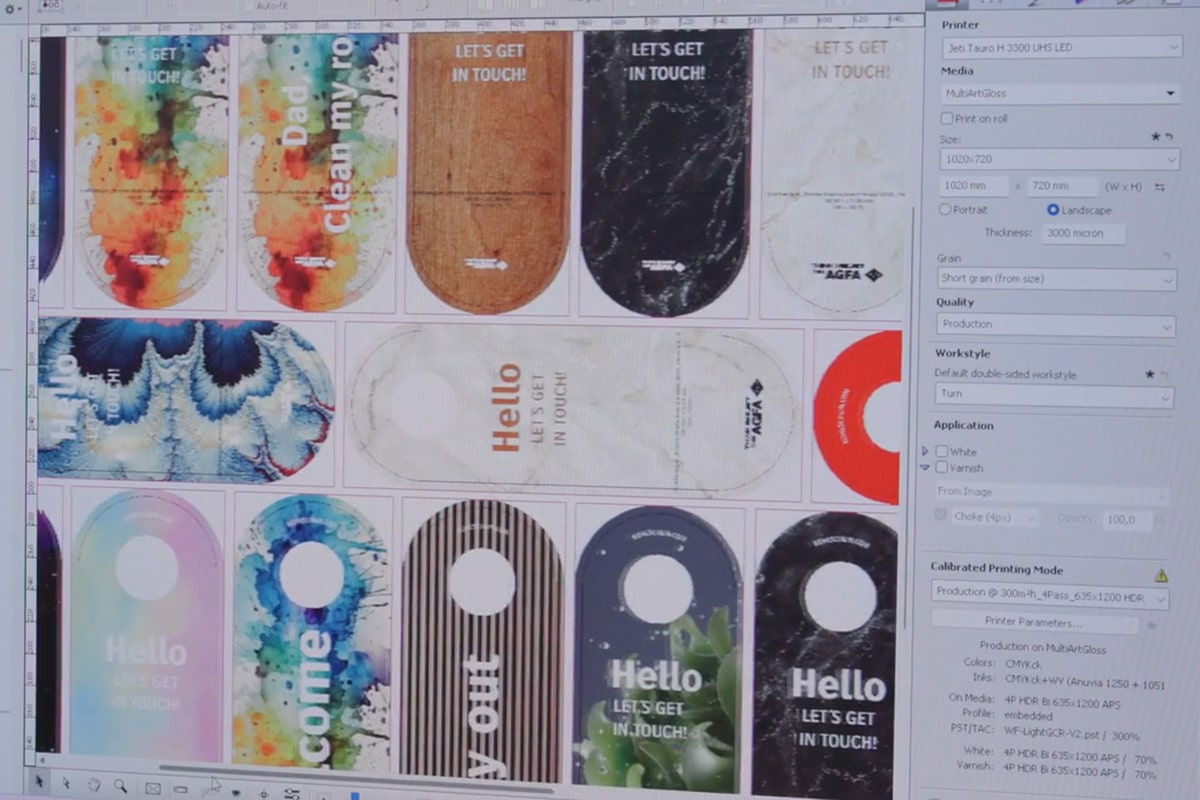

The Onset X3 HS enables single-cycle printing pushing productivity up to 1450m² per hour. It features Dimatix Spectra Printheads that deliver exceptional drop placement accuracy and reliability and uses Agfa high-quality ink suitable for many applications and materials. It also now uses the leading Agfa Asanti workflow software and utilizes robotic technology to automate various production and material handling requirements. N Smith & Co chose to upgrade and add full automation with dual robots and a ¾ laytable to their purchase to significantly boost productivity. They can now pre-position a variety of sheet sizes during the printing process ready for the handling system to remove printed sheets swiftly and load the next. The system can load up to three sheets at a time and has the precision to accommodate double-sided print accuracy.

Final word from MD Nigel, “Overall the Agfa team did a great job of providing us with what we needed to decide on this new machine. We didn’t make the selling process easy for them, we were determined to get the right product to future-proof the business at the right price and that takes frank discussions and negotiation. I’m pleased that the sale process is over, and we can now build on a long-term relationship.”