CONVENTIONAL VERSUS DIGITAL

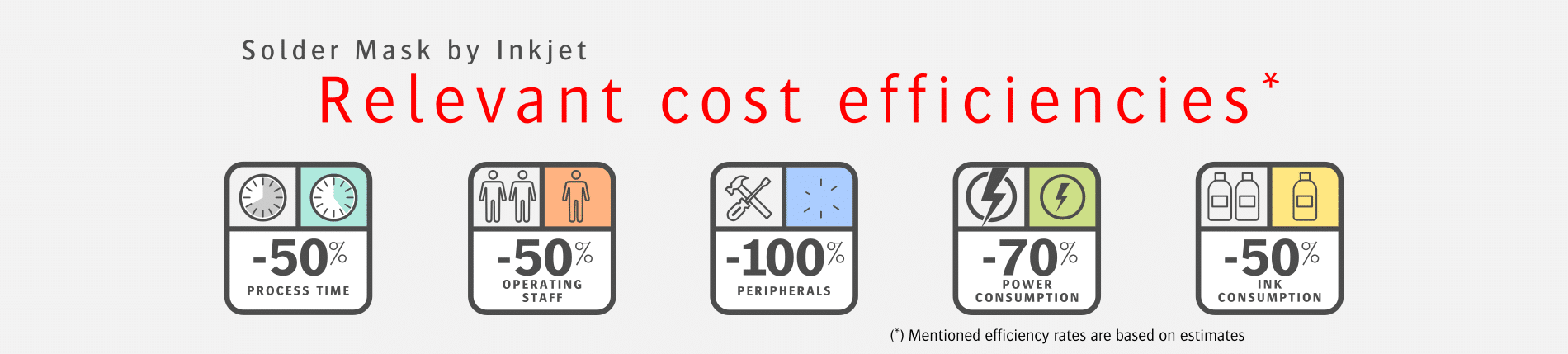

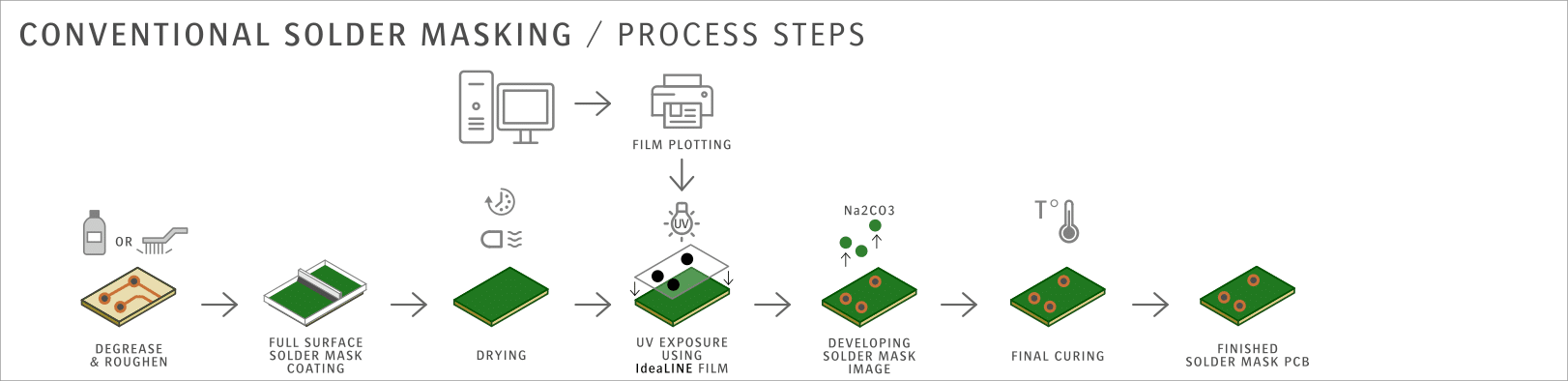

Cost pressure and the need for higher flexibility and efficiency drive PCB manufacturers to consider digital technology based on inkjet printing either as an alternative or a parallel production method next to the conventional lithographic process. Inkjet printing directly from CAD reduces the set-up time and infrastructure as well as the water and energy consumption. As an additive process, inkjet also eliminates material waste and is without a doubt the more environment friendly option for PCB manufacturing.

IdeaLINE PHOTOTOOLING FILMS FOR CONVENTIONAL SOLDER MASKING

Agfa offers a large portfolio of films categorized by exposure light source and resolution specifications to most adequately meet the widest range of case-specific requirements. IdeaLINE’s unsurpassed consistency in quality, very good dimensional stability, and optimal density translate into your PCB’s being manufactured with unparalleled precision of line and space widths.

IdeaLINE RPF, CKF & OPF films enjoy Agfa’s ‘hard dot’ technology that allows for extremely high contrast ratios and very sharp line edges. IdeaLINE SPF film is based on ‘soft dot’ technology with a somewhat lower contrast but giving a very wide imaging and processing latitude, which makes it a perfect fit for less critical production environments.

Symmetrical construction means that our double sided coated film types remain perfectly flat after chemical processing making it very simple to mount and hold phototools on the exposure unit. Single sided films have a superior dimensional stability coefficient thanks to a much lower level of gelatin. Controlled temperature and humidity make sure that the film stays nice and flat.

IdeaLINE CPF2 is a high resolution film that works with UV light. Unique in the market, it can be exposed on Laser Direct Imagers, which is a very good alternative or back-up for a traditional film plotter.

For best image results, it is advised to use IdeaLINE chemicals for processing.

About IdeaLINE

IdeaLINE is the brand name of the world’s N°1 portfolio of phototool films and chemicals. The films are extruded and coated in Agfa’s production center in Mortsel, Belgium. The manufacturing plant is certified ISO 9001 and ISO 14001 for Quality Management System and Environment Management respectively.

World-Class film technology. IdeaLINE includes both single sided and double sided phototool films that enjoy Agfa’s ‘hard dot’ technology. This technology allows for extremely high contrast ratios and very sharp line edges. All IdeaLINE films stay nice and flat so that mounting an holding the film on the exposure unit is perfectly simple.

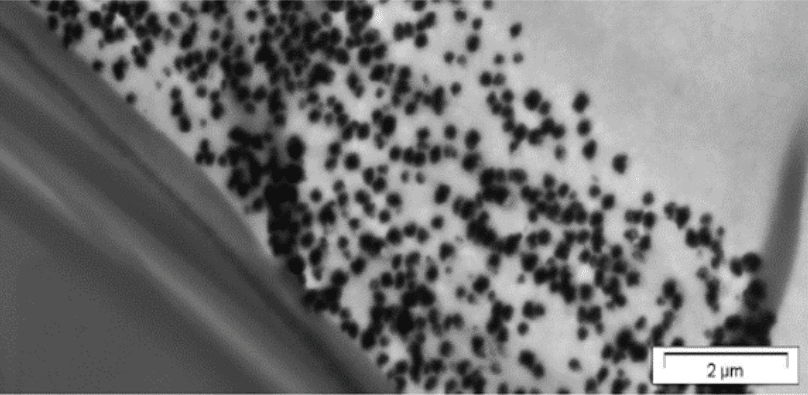

Agfa’s technology is based on nano-size silver particles (black spots in the photo) that are embedded in gelatin.

IdeaLINE films are securely packed, even the XXL sheets. IdeaLINE films are cut and packed in clean room environment. The cutting equipment is encapsulated and kept under a laminar HEPA filtered airflow. In addition, the films are cleaned by a contact surface cleaning system prior to stacking and are AOI inspected. Agfa offers phototooling films in an exceptionally wide range of sizes going up to even 162 cm x 245 cm. Most IdeaLINE film products are vacuum packed in a sleeve that contains a moisture barrier. Additionally, the vacuum pack is wrapped in a PE foil to block any dust that could come from the cardboard wrap.

The global N°1 supplier position of Agfa was achieved thanks to IdeaLINE’s sustained product quality which has been validated by all the major photoplotter vendors.

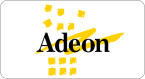

DiPaMAT SOLDER MASK INK REAPS THE BENEFITS OF DIGITAL INKJET PRINTING AT ALL LEVELS.

Digital solder mask inkjetting is vastly more efficient and economical compared to traditional processes or DI. Only the exact amount of ink is needed and only on the desired areas, no waste! The number of process steps and the environmental impact are therefore greatly reduced.

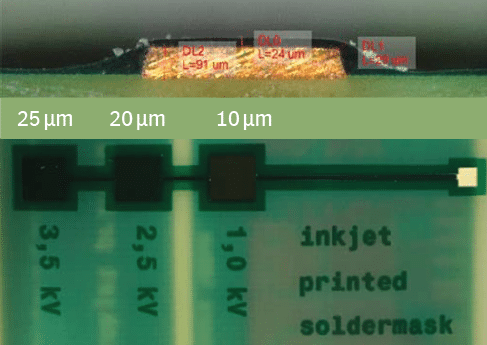

Inkjet printers customized for solder mask processing combine advanced print heads with sophisticated printing algorithms which results in a unique capability to vary thicknesses across the PCB surface in a truly additive way. Prime examples of what can be achieved with thickness variations are area specific resistance to breakdown voltage and optimized edge coverage. The unparalleled precision of ink deposition avoids unwanted ink blockages in vias and prevents solder bridges. DiPaMAT Solder Mask meets and goes beyond the IPC SM 840 standard. It has a high thermal resistance and passes the stringent requirements of the automotive industry.

VARIABLE THICKNESS

Thanks to their chemical composition DiPaMAT Solder Mask inks allow for multi-pass printing that delivers strongly cohesive layers. Variable thicknesses depending on the requirement can be applied on the surface of the same PCB. .

UNIQUE PRECISION

Precise ink deposition through digital inkjetting of DiPaMAT Solder Mask eliminates issues related to conventional printing processes such as obstructed vias and solder bridges.

VALIDATED & AWARDED

The prestigious IPC APEX Innovation Award was granted in 2019 to the inkjet solution for PCB manufacturing using Agfa’s DiPaMAT Solder Mask ink. DiPaMAT Solder Mask ink has been validated and endorsed by the major inkjet printing machine manufacturers around the world.

About DiPaMAT Inkjet Inks

All DiPaMAT inks are UV curable either with mercury bulb or LED. The inks are non-toxic and contain no solvents, hence they are environmentally friendly. DiPaMAT inks have a low viscosity, which allows for great printing efficiency within a wide range of printhead technologies. DiPaMAT inks meet all industry standards as well as health and safety regulations and are manufactured under ISO 9001.

Following Agfa’s vendor-neutral strategy, DiPaMAT inks are validated by major suppliers of industrial piezo print heads and printer integrators.

DiPaMAT Inkjet Inks for PCB have been validated by: