Meet Attiro VHS, the high-speed unit that cleans out your violet chemistry-free plates to perfection. It uses a unique cascade system, where the concentrated gum is effectively reused in three sections. In this way, the non-imaged areas are effectively removed and there is no risk of oxidizing. Full maintenance (with ATTIRO CareClean) is only required after 8,000 m², which drastically reduces gum consumption and waste.

The addition of the Attiro Cleaning Module (ACM) extends the main cleaning cycle for Attiro COUs even further – to 12,000 m² of plate consumption. Furthermore, the two intermediate cleaning processes at 4,000 and 8,000 m² are executed as part of an automated process that starts with a simple keystroke on the Attiro display and requires no further intervention from the operator.

The Attiro VHS clean-out unit forms a very attractive solution combined with N95-VCF chemistry-free printing plates, and the Advantage N TR (V)HS platesetter.

Benefits

Unique cascade concept

Three cascading gum sections efficiently reuse gum

Fully flat plate transport

Minimizes the risk of plate jams

Less transport of gum bottles

Thanks to reduced gum consumption

| Performance | |

|---|---|

| Plate type | N95-VCF chemistry-free photopolymer offset plates |

| Plate width, min. – max. | 200 – 710 mm (7.9 – 28”) |

| Plate length, min. | 275 mm (10.9”) |

| Plate thickness, min. – max. | 0.15 – 0.30 mm (0.006 – 0.012”) |

| Platesetters (Agfa) | Advantage N |

| Plate speed | 40 – 250 cm/min (40 – 300 cm/min for the Attiro VHS) |

| Plate volume | Up to 400 plates/hour |

| Brush speed | Gum 1: 200 rpm (fixed) |

| Gum 2: 150 rpm (fixed) | |

| Water | Total hardness < 6° dH) |

| Connection: 3/4 gas | |

| Drain tube: inner diameter 25 mm | |

| Max. pressure | 3 bar |

| Mechanical specifications | |

|---|---|

| Temperatures | Pre-heating min.-max.: 20 – 160°C (68 – 320°F) |

| Dryer min.-max.: 20 – 70°C (68 – 158°F) | |

| Dryer temperature for Avatar V-ZH plate processing: min. 49°C or 120°F” | |

| Tank volumes | Gum 1: 7.5 lit. (1.98 US gal.) |

| Gum 2: 5.5 lit. (1.45 US gal.) | |

| Gum 3: 4.5 lit (1.19 US gal.) | |

| Noise emission (max.) | < 70 dB |

| Physical specifications | |

|---|---|

| Weight cleaning module | 285 kg (628 lb) |

| incl. crating: 385 kg (848 lb) | |

| Weight pre-heating module | 218 kb (480 lb) |

| incl. crating: 318 kg (701 lb) | |

| Dimensions cleaning module (w x d x h) | 1550 x 1350 x 1220 mm (61.0 x 53.2 x 31.5”) |

| Dimensions pre-heating module (w x d x h) | 1550 x 1350 x 1220 mm (61.0 x 53.2 x 31.5”) |

| Electrical specifications | |

|---|---|

| Machine power | EUR: three-phase / 3W + N + PE – 400V / 14Amps, 50/60Hz. |

| USA: three-phase / 3W + PE – 208 – 230V / 23Amps, 50/60Hz | |

| Voltage tolerances | +/- 10% |

| Power consumption EUR/US | 9000 Watt hour (30717 BTU) |

| Energy consumption (under standard working conditions for 1 h) | Ready (Standby): 2.0 kWh |

| Processing: 4.0 kWh | |

| Logic off (device switched off via touch panel only, main switch remains on): 0.02 kWh |

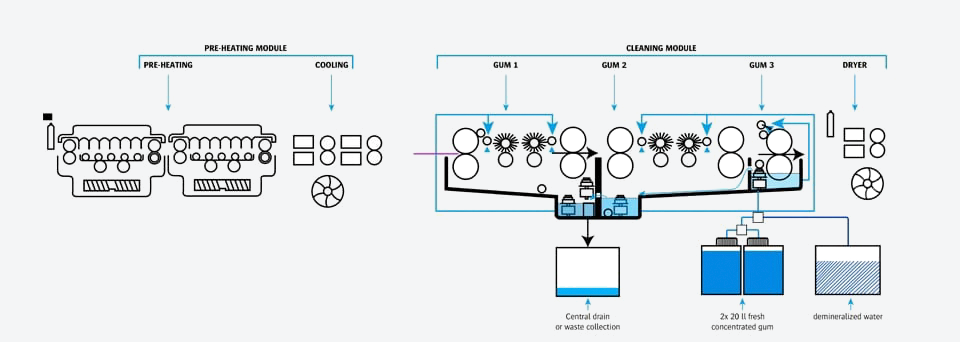

How the unique cascade concept works

PRE-HEATING MODULE

Pre-Heating

The emulsion of the exposed plate is hardened using a high-tech hot-air oven. A sensor ensures a uniform and stable temperature on the plate.

Cooling

The plate is cooled to enable immediate cleaning. The plate is cooled to an optimum temperature, which prevents overheating of the liquids in the subsequent sections.

CLEANING MODULE

Gum 1

95 % of all non-imaged areas are removed from the plate. Gum is sprayed on the plate. The imaged areas are bonded to the substrate and, therefore not removed by the gum. The gum is actually cascaded into the first tank from the second tank. As most of the clean-out happens in the first gum section, it contains most of the cleaned out emulsion. From this tank, the exhausted gum is drained off.

Gum2

The remaining non-imaged areas are removed from the plate. The gum mix from the third tank cascades into the second tank, and pushes the gum used for the second cleaning step away. It then cascades into the first tank.

Gum3

A layer of fresh gum is applied to prevent the plate from oxidizing the grained and anodized aluminum. The final clean-out step is carried out with concentrated gum fresh from the bottle, thus ensuring a perfectly clean plate. The fresh gum and water from the tank in the third section then cascade into the tank of the second section.

DRYER

The plate is dried to enable immediate handling, independent of the plate format. Hot air is blown through a pair of air tubes, which dries the plate on both sides. As a result, further handling of the plate is immediately possible.