Générer de la valeur avec les solutions ECO³ d’Agfa Graphics

Économie, écologie, confort supplémentaire – ou résumé en un seul mot : ECO³. Ce sont les avantages clés qui caractérisent les innovations de dernière génération d’Agfa Graphics pour l’industrie de l’impression. L’accent n’est pas seulement mis sur le solide portefeuille bien connu de la société dans le domaine du prépresse, mais également sur l’amélioration de la qualité, de la productivité et de l’efficacité dans l’environnement des salles de presse. Agfa Graphics souhaitent démontrer aux imprimeurs comment ils pourraient alors tirer encore meilleur parti de leurs investissements.

Que signifie l’acronyme ECO³ ?

“ECO³ est synonyme d’écologie, d’économie et d’extrême commodité“, explique Joan Vermeersch, vice-président de la technologie, du marketing et du développement des activités Prépresse au sein d’Agfa Graphics. “Le terme ‘Éco’ est utilisé depuis de nombreuses années pour désigner des solutions respectueuses de l’environnement. Pourtant, les deux autres lettres E sont toutes aussi importantes pour une imprimerie. Dans le domaine de l’impression offset, nous nous concentrons sur la transformation de technologies en solutions durables qui créent une réelle valeur pour nos clients. L’impact environnemental de ces solutions est certes un facteur important, mais nous ajoutons aussi le coût total des opérations et la notion de praticité dans l’équation. Nos innovations sont toujours basées selon les besoin du marché.”

“Nous cherchons à rendre ‘ECO³’ l’ensemble du portefeuille de nos solutions”, déclare M. Vermeersch. “Nous avons une longue antériorité de réalisations en matière de développement durable. Avec l’introduction de la plaque d’impression Azura en 2004, nous avions été les premiers à oeuvrer pour lancer des solutions prépresse sans chimie, et nous sommes toujours le leader de l’industrie. En parallèle, nous continuons également d’améliorer le mode conventionnel pour qu’il s’intègre au cadre ECO³. Le développement durable fait intégralement partie des exigences techniques de tous nos projets de R&D pour les nouveaux systèmes, qui sont également évalués en termes de qualité, de performance et de coût.

Du prépresse à la presse

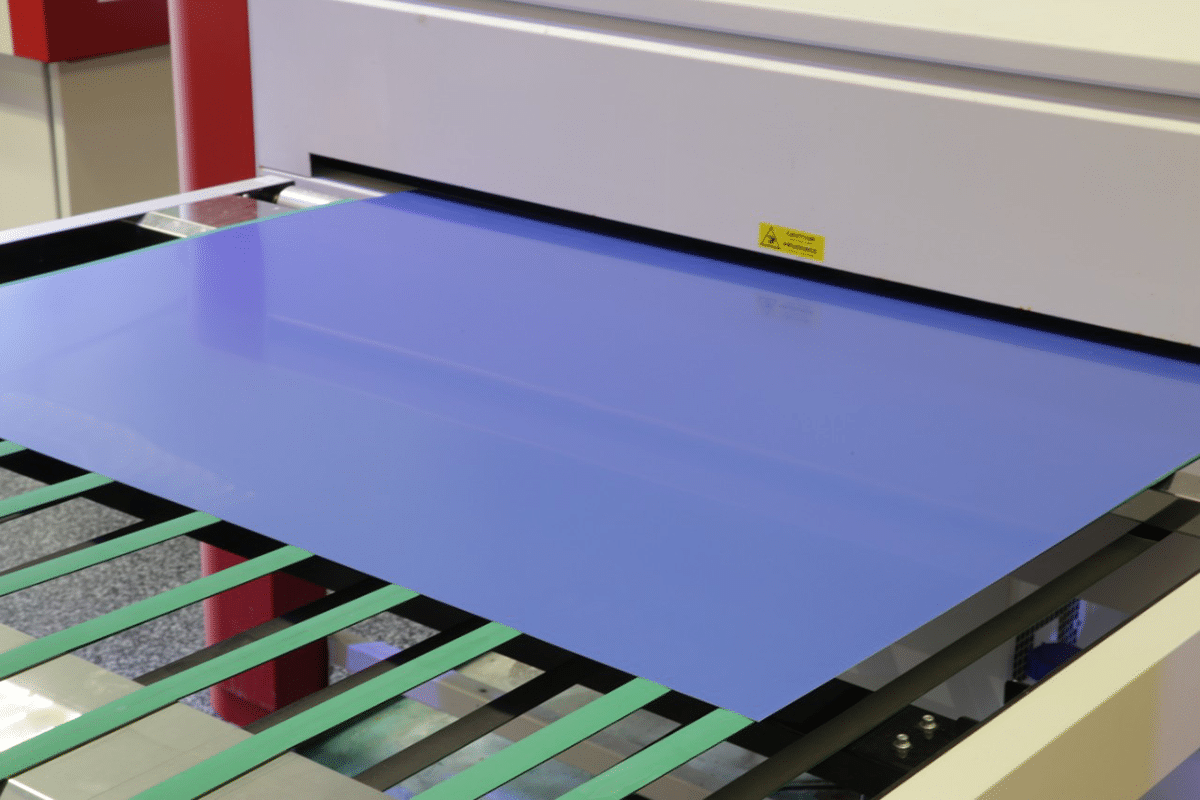

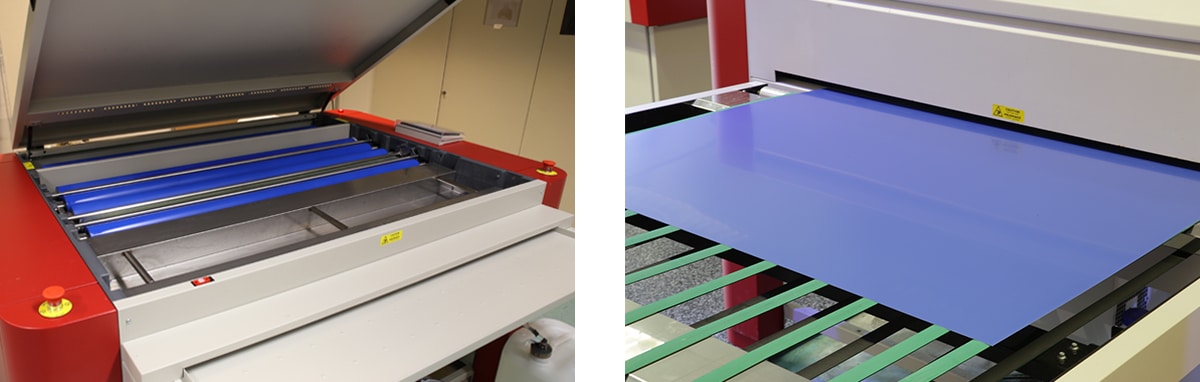

“L’un d’entre eux est incontestablement la plaque d’impression Energy Elite Eco. Elle est la référence absolue des plaques thermiques positives sans cuisson avec la meilleure longueur de tirage (jusqu’à 600 000 exemplaires), et compatible à la fois mécaniquement et chimiquement avec les exigences propres aux applications offset feuilles et rotatives avec sécheur. Combiné avec la technologie innovante de traitement intelligent Arkana des plaques, avec ses taux de régénération extrêmement faible et la suppression complète d’eau de rinçage – les déchets s’en trouvent réduits jusqu’à 50%. Cela réduit non seulement l’empreinte écologique d’une imprimerie, mais signifie aussi moins de transports et de livraisons, moins d’espace de stockage, moins de manipulation et moins de bidons vides à recycler. De plus, la chimie plus propre de la plaque d’impression Energy Elite Eco utilisée dans l’unité de traitement permet un nettoyage facile et rapide, et prolonge la durée de vie du bain jusqu’à 15 000 m² de plaques traitées (soit 3 fois plus qu’un système conventionnel).”

M. Vermeersch ajoute : “Les autres avantages de l’ECO³ sont illustrés par le CtP Avalon N8-90, qui permet d’atteindre des niveaux de productivité extrêmement élevés, avec 71 plaques/heure au format B1, mais aussi par nos solutions Cloud particulièrement innovantes. Nous sommes les seuls à intégrer les flux de production des imprimeurs dans le Cloud, ce qui permet aux entreprises de minimiser leurs coûts d’exploitation, tout en garantissant la continuité et la sécurisation de leurs activités. Il convient d’ajouter à cela notre solution exclusive de gestion et de partage de fichiers, ainsi que notre module professionnel de Web-to-Print.”

L’offre d’Agfa Graphics ne s’arrête pas là où s’arrête l’environnement prépresse. Comment faites-vous aussi une différence dans le département impression ?

“En effet, un large éventail de nos solutions apporte des améliorations significatives et des économies dans l’atelier impression. Un logiciel comme Apogee Impose par exemple, peut minimiser la gâche papier en calculant des impositions intelligentes. Une plaque comme Energy Elite Eco permet une grande latitude en presse et présente d’excellentes performances lithographiques, ce qui permet des redémarrages rapides, des effets modérateurs et un équilibre encre-eau stable – qui se traduisent par des économies de temps et d’argent. La plaque a également une résistance chimique exceptionnelle. Cela signifie plus de flexibilité dans le choix des fontaines, solutions de lavages et nettoyeurs de plaques. Son excellente robustesse mécanique permet de réduire les risques d’usure ou réfection de la plaque, et leurs divers coûts associés. Nos divers consommables spécifiques destinés aux presses ajoutent eux aussi de la valeur. Des consommables qui comprennent les blanchets et rouleaux de lavage, les additifs de fontaine et produits complémentaires qui prolongent la durée de vie des plaques d’impression, des blanchets et des rouleaux, et contribuent tous à améliorer à la fois le temps de fonctionnement de la presse, et la stabilité des tirages.”

Nul part ailleurs, les imprimeurs n'obtiendront un aussi bon rapport qualité-prix. Nous nous engageons à fournir la plus haute qualité de produits et de services, pour permettre à nos clients de développer leur activité de manière rentable. C'est pourquoi nous investissons dans l'innovation durable en mettant l'accent sur l'écologie, l'économie et la commodité - d'où la dénomination ECO³. Outre nos solutions prépresse plus écologiques et plus économiques qui sont toutes plus faciles à utiliser et à entretenir ; nos solutions logicielles nouvellement introduites permettront aux imprimeurs de bénéficier d'une automatisation et d'une gestion de la qualité améliorées, ce qui se traduira par des économies impressionnantes tant en prépresse qu'en presse.

“Récemment, nous avons également publié un véritable combiné de puissance avec l’introduction des progiciels PressTune et InkTune. Ils ajouteront de la valeur en réduisant les coûts, tout en améliorant la qualité et la productivité dans les départements prépresse et impression. PressTune est un outil complet de standardisation de l’impression qui assure le respect et la correcte correspondance des couleurs selon des normes précises, et de garantir la cohérence des couleurs tout au long du tirage. Grâce à une analyse de tendance en production, il permet aux imprimeurs de suivre, gérer et améliorer les performances de la presse et de l’opérateur. En tant que tel, il réduit le temps de mise en route jusqu’à hauteur de 40% et de 5% la gâche lors de l’impression. InkTune applique des calculs intelligents qui affinent les paramètrages de la presse afin d’augmenter la rentabilité des opérations d’impression. Il réduit la consommation d’encre jusqu’à 30% tout en conservant ou même en augmentant la qualité d’impression. Il améliore également la stabilité de la couleur sur la presse, ainsi que la qualité et la reproduction tout au long du tirage, permettant de caler et d’imprimer plus vite avec des temps de séchage bien plus rapides. Les deux logiciels fonctionnent à merveille lorsqu’ils sont combinés ensemble.”

Écrit noir sur blanc

Vous promettez aux imprimeurs une réelle valeur ajoutée et des économies. Comment allez-vous leur prouver cela ?

“Nous proposons aujourd’hui à tous les imprimeurs de pouvoir réaliser un calcul détaillé de leurs économies potentielles. À cette fin, nous avons développé un calculateur de valeur qui compare notre offre à des systèmes concurrents ; et qui prend en compte le matériel, les logiciels et consommables utilisés. Dans ce module d’évaluation, nous prenons en compte un large éventail représentatif de paramètres inhérents aux départements prépresse et impression : consommation d’eau, consommation d’énergie, utilisation de révélateur ou de gomme, coûts de main-d’œuvre, coûts d’entretien, coûts d’élimination des déchets, première bonne feuille (“sèche”), etc. Notre calculateur génère ensuite un rapport factuel détaillé qui résume – en volume comme en argent – les gains potentiels pour un client.”

>> Découvrez comment vous allez pouvoir économiser de l’argent sur www.eco3.graphics