RAW MATERIAL ANALYSIS

of polymer pellets (case 02)

QUESTION:

Why is my product not stable?

A polymer-based product started to behave instable during production and its properties (imaging sensitivity) varied.

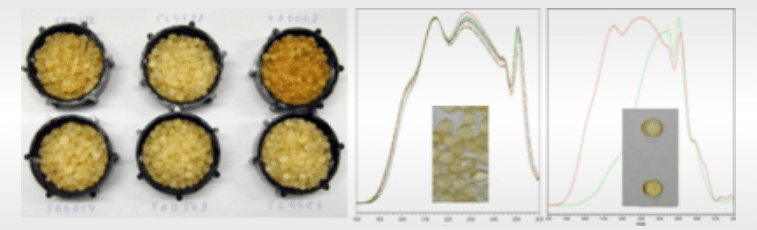

One of the main base materials was delivered in the form of polymer pellets. The color of the pellets had always revealed significant color differences, from batch-to-batch, but also within a single batch. However, these known variations in color were never related to any problem in past productions.

APPROACH:

Raw material analysis

We checked the molecular weight distribution of probes from the various batches. Surprisingly, only small differences between the various batches were found, irrespective of the strong visual color differences.

Inspecting the pellets more in detail, the raw material analysis not only identified color differences, but also shades of clarity and haze. Those clear and hazy pellets systematically showed differences in their large molecular weight distribution.

Via NMR spectroscopy the clear species was identified to contain a cresol type of resin whereas a fenol type resin was found in the hazy pellets.

RESULT:

Cross-contamination discovered

The supplier was confronted with these findings and confirmed a cross-contamination: a reactor for synthesis of the pellets had insufficiently been cleaned, resulting in variable resin contamination of the polymer pellets.

Want to know more about raw material analysis?

Let's Talk

Fill out this form, and we'll revert to you as soon as possible.

Please provide a detailed description of your question or request.