HARDNESS AND ELASTICITY

using Nano Indentation (case 28)

QUESTION:

What is the hardness and elasticity of my materials ?

The hardness of a material is an important mechanical property that is a measure of the local resistance to plastic deformation, as is the elasticity.

The materials can range from small particles, with a cross-section of several micrometres, to thin and multilayers coatings, including photoresists, paints, lacquers, and many other types of films, covering optical, micro-electronic, protective, decorative and other applications.

The range of substrates can cover hard or soft, rough or smooth materials including metal alloys, semiconductors, glass, refractive and organic (plastic) matter.

As reproducibility is key, applying well-defined indentations on the material surface is needed for the characterization of the mechanical properties.

APPROACH:

Nano-hardness testing with NHT 3

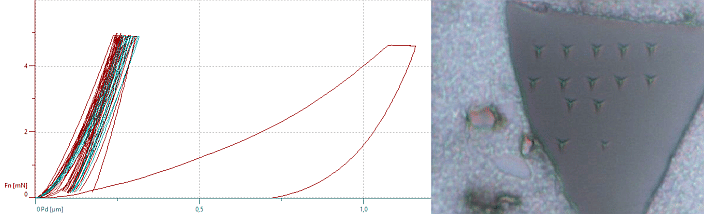

A diamond indenter (Berkovich tip geometry) is used to apply a normal load Fn onto the sample surface. An appropriate loading rate is chosen for the desired application.

When the indenter experiences either the maximum defined load or penetration depth, the tip will remain in position for a chosen timespan. Then, the sample is unloaded at the desired unloading rate. It is important that the tip does not penetrate the layer that needs to be measured.

The nano-indenter accurately measures the penetration depth and normal force. Using the Oliver & Pharr Power Law method, the load/displacement curve can be analysed. This method gives insight into the hardness and elasticity of a material. But also the viscoelastic behaviour of the material can be investigated using the nano-indenter.

Taking a microscopic image of the performed indentations is a convenient check to make sure the indentation was successful and the material did not crack.

RESULT:

Better understanding the local hardness and elasticity on nano-scale

Thanks to the precise measurements taken by the nano-indenter, a detailed characterization of surface properties of your material is possible.

In-depth analysis of the penetration curves allows for a better understanding of the local conditions, which can be used to further optimise your product.

Let us carry out nano-indentation testing for you.

Let's Talk

Fill out this form, and we'll revert to you as soon as possible.

Please provide a detailed description of your question or request.