SCRATCH TESTING

on materials (case 24)

QUESTION:

How sensitive is my material to scratches and wear?

Scratches can be found on many different soft and hard coatings as a first step of mechanical wear. Examples are thin and multilayers coatings, including photoresist, paints, lacquers, and many other types of films, covering optical, micro-electronics, protective, decorative and other applications. Range of substrates can cover hard or soft, rough or smooth materials including metal alloys, semiconductors, glass, refractive and organic (plastic) matter.

Applying well-defined scratches in a reproducible manner is key when aiming characterization at resistance of surfaces to mechanical wear.

APPROACH:

Nano scratch testing with NST 3

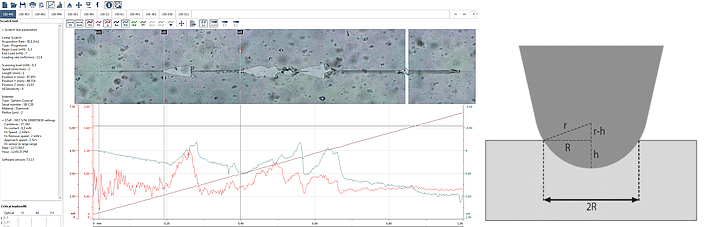

A diamond stylus (spherical diamond tip geometry) is used to apply a normal load FN onto the sample surface. Then, the sample is displaced at a constant speed while the normal load is progressively increased. At some point, the tip penetrates the surface and the resulting stresses may introduce flaking or chipping of the coating.

The critical load (Lc) at which a specific failure event occurs can measured from the fluctuation in the tangential force, from the acoustic emission signal or can be observed as specific surface deformation in the optical microscope image, which is captured in register to the force measurements. Lc can also be detected as a discontinuity (step) in the post-scan surface, which also allows observation of eventual recovery (“self-healing”) of the surface.

Dimensions of the tip influence the results and are therefore chosen together with the level of normal load to represent scratches observed in field use.

See AgfaLabs’ NST3 Nano scratch test system.

RESULT:

Better understanding the causes of mechanical wear

The detailed characterization of surface damage by scratching provides a fundamental understanding of processes that finally result to mechanical wear.

Differentiation of the mechanical failure modes on Nano-scale can be used to inspire improvements of the coating formulation and to understand the functional impact of scratches on coatings.

AgfaLabs can carry out scratch testing for you.

Let's Talk

Fill out this form, and we'll revert to you as soon as possible.

Please provide a detailed description of your question or request.