IN-DEPTH OPTICAL ANALYSIS

of synthetic paper (case 14)

QUESTION:

Optical analysis to optimize paper performance

AgfaLabs was asked for an in-depth optical analysis to reduce the number of experimental synthetic paper formulations. Optimization of the optical performance of synthetic paper began with a benchmark of the scattering efficiency of air inclusions versus that of white pigments.

Air inclusions are introduced during the stretch of PET film with its co-extruded SAN inclusions. In particular, the effect of total vol% of scatterers and their number size distributions on both optical opacity and reflection color of a synthetic paper of given thickness were relevant.

APPROACH:

Optical modelling for paper analysis

We proposed optical modelling for the in-depth paper analysis. Due to the complex geometry of the scattering inclusions, we mutually agreed to limit the efforts to a semi-quantitative approach in which the complex shape of the non-spherical air inclusions was correlated to sphere-equivalent dimensions of ‘effective scatterers’.

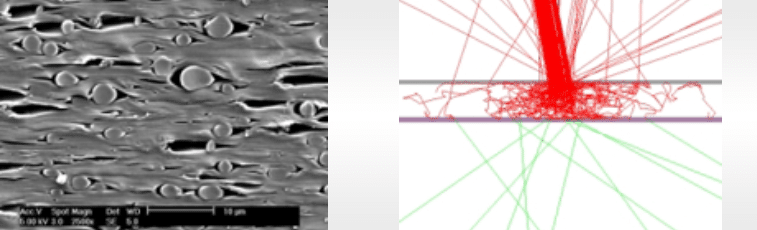

We implemented the effective optical model in a spectral ray tracing software. Set-up was inspired by SEM images that were also used to estimate the size distribution of air inclusions, which is a function of process parameters and initial particle size distribution of the SAN particles.

Finally, both types of candidate scattering inclusions (air inclusions and white pigments) were foreseen in the model to allow their virtual blending for trade-off considerations. We checked the model quantitatively against spectral reflection and transmission characteristics of a number of test materials with different formulations and process parameters, and found overall good correlation between model and experiment.

RESULT:

Efficient development and optimization

With the optical model of synthetic paper at hand, a number of semi-quantitative trade-off rules were formulated for use in the product optimization, especially number, size and optical properties of the inclusions.

The model-based understanding of the interplay of the key parameters for this product reduced the number of costly and time-consuming extrusion experiments considerably and helped speeding up the development phase.

Also, the maximum acceptable parasitic absorption of the binder matrix (PET) was quantified, which serves as a specification for the raw material. Otherwise, an unwanted greyish tint would shine through in the final product.

AgfaLabs can carry out an in-depth optical analysis or another paper analysis for you.

Let's Talk

Fill out this form, and we'll revert to you as soon as possible.

Please provide a detailed description of your question or request.